FAQ

FAQ

1. Why are your uppers more expensive than others on the internet that look the same?

2. Who makes your barrels and upper assemblies and do your barrels have M4 ramps?

3. What does barrel twist rate mean?

4. What is QPQ?

5. Do I need a chrome lined or QPQ barrel?

6. Who makes your free float rails?

7. What parts do I need to have a complete rifle?

8. What configuration would be best for me?

9. What is your Warranty?

10. What is your accuracy guarantee?

11. What do I do if my rifle/parts arrive damaged?

12. What do I do if I have this problem with my rifle/assembly?

13. Will your stuff fit my stuff?

14. Is 5.56 the same as .223?

15. What other calibers than 5.56 are available?

16. Do you sell piston systems?

17. Why are there sometimes price differences depending on where I look?

18. Will you build my assembly using my components?

19. How long have you been in business?

20. How long is your processing time?

21. What is the difference between a A2 Front sight and a F-Marked?

22. Do you use taper pins to install your Front Sight Base?

23. Are your barrels coated (finished) under the Front Sight Base?

24. Gas Port Sizing

25. Custom Uppers and customization

26. Do you take phone orders?

27. Do you have a store front?

28. I forgot my password and the link isn't working?

29. Why is the inside of my upper grey?

30. What does manual verification mean?

31. What are the ramp types.

32. I want to use my po box as my physical address.

1. Why are your uppers more expensive than others on the internet that look the same?

It is because of quality factors that are not readily apparent from looking at a picture on the internet or at a photo in an ad. Although all AR-15 style rifles are theoretically built to the same dimensional specifications, there are significant differences in manufacturing processes that greatly affect the quality of the product. For more details on what this means, read the About Us page.

Everything TNTE Sales Inc. uses in our builds is made in America from top quality manufacturers TNTE machines nothing on our own and we do not use machine shops located in pole barns behind someone’s home that specialize in cranking out low-end commercial grade parts. We let those who have years of experience and high-quality control measures already in place make our stuff.

2. Who makes your barrels and upper assemblies do your barrels have M4 ramps?

The question here isn’t really who makes the barrel blank, but who machines the barrel blank and upper receiver into a finished product. Typically, our blanks come from E.R. Shaw, Creed Monarch (CHF) or Green Mountain Rifle Barrels. Our Chrome Moly barrels are 41V50 steel, our Chrome Lined and QPQ Barrels are 41v50 11595E Mil-Spec quality Steel unless otherwise noted. Our suppliers cut, finish, and chamber all our barrels unless otherwise noted. TNTE Sales Inc. assembles, times, headspaces all uppers. Our receivers are milled from Cerro Forge (Keyhole Forage Mark), Anchor Harvey (Broken A Forge Mark), Brass Aluminum (Square Forge Mark) or Cardinal forgings (Bird Head Forge Mark), Black type 3 hard coat is our go to finish.

Other US Government Contract Parts Houses manufacturer our small parts and bolt carrier group assemblies to our highest specifications.

All TNTE bolts are shot peened and Magnetic Particle Inspected (MPI) and contain the heavy-duty black extractor spring insert. TNTE Sales Inc. then adds a Mil-Spec Viton(r) O-ring to the extractor spring assembly to virtually eliminate failures to extract.

TNTE Sales Inc. inspects, and hand assembles each upper assembly to strict tolerances and function tests the complete unit again to ensure that only the most accurate, durable, and reliable upper assembly is delivered to you. When your upper gets to you, you know your upper works and works well!

M4 ramps are standard on all our 5.56 1/7,1/8,and 1/9 barrel. 1/12 and 1/14 barrels have rifle ramps unless otherwise stated.

3. What does barrel twist rate mean?

Barrel twist rate is a measure of how fast the rifling inside the barrel spins the bullet in order to stabilize it in flight and thus make it more accurate. A 1 in 9 (1:9) twist rate means the barrel rifling completes one revolution every nine inches of barrel. If the twist rate is too slow, the bullet will “wobble” in flight and thus be significantly less accurate. If the twist rate is too fast, the high rpms can cause the jacket of the bullet to fail-- centrifugal force literally tears the metal jacket off the bullet core.

What barrel twist rate is ideal for you is determined by what type of shooting you wish to do. Generally, the heavier the bullet you wish to shoot, the faster the twist rate needed to stabilize it in flight (Stabilization is dependent on the length of the bullet not necessarily the weight. For most practical purposes, the heavier bullets tend to be longer). TNTE Sales Inc. recommends the following as a general guideline:

1 in 9 twist rate (1:9) 45 gr. to 69 gr. bullets

1 in 8 twist rate (1:8) 45 gr. to 77 gr. bullets

1 in 7 twist rate (1:7) 55 gr. to 80+ gr. bullets

NOTE: The maximum bullet weight that can be fired from the standard GI magazine due to the overall length of the cartridge is 77 gr. Any cartridge with a bullet heavier than 77 gr. will not fit in the magazine and will need to be loaded individually by hand.

4. What is QPQ?

QPQ stands for quench, polish, then quench again to ensure the entire barrel is coated. It is a salt-bath nitride, which provides for a longer barrel life than chrome-lining. The barrel extensions are installed but not torqued to spec until after the QPQ process is complete, to ensure the extension will not come loose. The QPQ process has shown to have much better resistance to throat erosion than chrome lining, without affecting accuracy.

5. Do I need a chrome lined or QPQ barrel?

For certain applications, it is the only way to go. Those applications are primarily full-automatic applications where you will shoot a lot of bullets in a rather short period of time. The military is interested in a barrel life of over 8,000 rounds (up to 12,000 rounds) so thus they require chrome lining. With new technologies, the standard chrome-moly barrels now combine the best of a standard steel barrel with the addition of chrome in its mixture. A properly maintained chrome-moly barrel today has an upper life of over 8,000 rounds. That is a lot of bullets.

Chrome lining was originally applied to barrels to prevent corrosion when the ability to properly lubricate your barrel was not always available. Today, however, so much lubricant is built into modern ammunition that the best way to protect your barrel is to pull the trigger every now and then.

Chrome lined barrels are also less accurate than standard CM barrels, QPQ, or stainless-steel barrels. The military is thrilled with being able to hit a dinner plate at 300 yards. As a chrome lined barrel wears, this is not a bad average. Most civilian and law enforcement applications require greater accuracy.

TNTE Sales Inc. recommends spending nearly the same amount of extra money on a QPQ barrel where you get increased barrel life and increased accuracy rather than settling for the drawbacks of chrome lining.

6. Who makes your free float rails and sights?

TNTE Sales Inc. uses free float rails and detachable sights from Daniel Defense, Centurion, KAC, Geissele, Troy, and Midwest Industries.

7. What parts do I need to have a complete rifle?

In order to put together your own custom rifle, all you need is a complete upper assembly and a complete lower assembly. The two assemblies attach together via two pins, the pivot pin and the takedown pin. It is that easy!

8. What configuration would be best for me?

That would depend on the reason(s) you want an AR style rifle. Contact us and we would be happy to discuss your needs and make a recommendation. sales@tntesales.com or 262.749.1370

9. What is your Warranty?

Our complete custom upper assemblies have a limited lifetime warranty against manufacturer defects (normal wear and tear is not covered). Upper assemblies without BCG and charging handle are covered with a 30-day limited warranty. Parts have a 30-day warranty. We will repair and/or replace any upper that is defective due to manufacturer defect. We do not issue return labels for warranty work. If the problem determined to be caused by customer supplied components (i.e. customer supplied BCG, charging handle, improper installation, & etc.), customer will be responsible for all shipping costs, charged for all repairs (parts, ammunition, and shop time) at our current rate. Current rate is $65 per hour with a minimum one-hour charge.

10. What is your accuracy guarantee?

Our accuracy guarantee is as good as you can shoot. It is unlikely that you can shoot better than our rifles will allow you to. With all the variables, like you, the ammunition, wind, temperature, and humidity, we would recommend you read the “fine print” of any accuracy guarantee that anyone else gives you.

Essentially there is no accuracy guarantee except as more of a function of how we treat our customers. If you discover a manufacturing defect that we missed, contact TNTE Sales Inc. at the time you receive your assembly, or after, we want you to call us. It is in our and our supplier’s best interest to know if there is a glitch in the manufacturing process. We will be happy to direct you on how to return the item for inspection and exchange.

11. What do I do if my rifle/parts arrive damaged or my package is missing?

We will assist you in every way possible with any problem you may have. If product arrives damaged from shipping, you must immediately call UPS as they carry insurance to cover products damaged during shipping. It left our hands intact and operational, so if it arrives damaged it happened during shipping. Take pictures of the damage, box including label and all contents. Then get on the phone to UPS first and report the damage. DO NOT FILE A CLAIM! If you file a claim there is nothing else, we can do. We have to file it. All damage claims must be reported to us within 3 working days of receipt.

Missing packages, we must file the claim with UPS, please notify us as soon as the package is late by more than two working days. Please allow up to 30 days for the investigation to be resolved. We may refund or replace depending on availability of items at the time.

12. What do I do if I have this problem with my assembly?

A. Question: I am having failure-to-feed issues! Answer: LUBE IT!! We cannot stress this enough; most failure issues are from lack of lube. Try several different magazines and several different types of ammunition (Don’t just switch from box 1 of cheap surplus ammo to box 2 of cheap surplus ammo. Switch to new commercial ammo from different manufacturers). This should take care of the problem. We function tested the assembly before we shipped it to you. When it shipped your upper worked perfectly. Break in should be done after cleaning and properly lubing the upper. Only use full power ammunition (supersonic for rifle) for the first 300 rounds. Subsonic ammo should only be used with a suppressor unless you have tuned your lower to cycle without the added backpressure.

B. Question: Upon extraction, I wind up with ripped-out shell casings remaining in the chamber!

Answer: Clean the chamber. Lubricate the chamber area correctly. If necessary, gently buff the chamber area with a light compound such as Flitz. Stop using cheap surplus ammo. We function tested the assembly before we shipped it to you. When it shipped your upper worked perfectly.

With the process, we go through of individually inspecting each part, hand assembling each upper, and function testing each assembly, manufacturer’s defects should be extremely rare. The only variables from our shop to you are the ammunition, the magazines, and the lubrication/cleanliness of the product. With proper cleaning and lubrication, especially when your assembly is new, the above steps should solve 99 out of 100 problems. If it doesn’t, give us a call and we will make it right. We are in business to do what is right and fair. We ask you to do the same. TNTE Sales Inc. is in business to earn your trust and your repeat business.

13. Will your stuff fit my stuff?

That depends on what you have. We sell only USGI dimensioned parts and assemblies so they will fit any other USGI dimensioned AR-15 style rifle. Only you know what you have so the answer depends on you.

14. Is 5.56 the same as .223?

Although .223 is the civilian designation of the 5.56 x 45 NATO round, they are not identical. A barrel chambered for 5.56 NATO can safely shoot .223 ammunition, but a barrel chambered for .223 Remington cannot safely shoot 5.56 NATO. ALL TNTE 5.56 BARRELS ARE CHAMBERED 5.56 NATO unless noted.

15. What other calibers than 5.56 are available?

There are many other calibers available for your AR style rifle that require only a different upper assembly and a different magazine to function. TNTE Sales Inc. can build assemblies in 5.56, 308win (.243win, 6.5 Creedmoor, AR-308 based etc...), 300AAC, 6.5 Grendel, 9mm, 7.62mm x 39, 6.8mm and .22 LR. 308.

16. Do you sell piston systems?

Yes, we can get upper assemblies and even get conversion kits for your existing upper assembly. Give us a call or send us an email to check on pricing and availability sales@tntesales.com or call 262.749.1370

17. Why are there sometimes price differences depending on where I look?

We do our best to keep prices on the website accurate and up to date. However, we are human and sometimes mistakes happen, we correct this by saying we are sorry and then stating the correct price. Sometimes we fail, so if you want the latest on anything, check the website and then give us a call or send us an email.

18. Will you build my assembly using my components?

Yes, we will use any quality component that the customer would like to provide.

19. How long have you been business?

We were established in 2011.

20. How long is the Processing Time?

We are a small shop so please be patient while we process your order.

UPPERS SHIP VIA UPS!!! YOU MUST PROVIDE A PHYSICAL ADDRESS FOR SHIPPING. IF YOU DO NOT YOUR ORDER WILL SHIP TO THE BILLING ADDRESS.

All semi-custom production uppers (non-quick ship) are subject to demand and product availability. Typically, they will ship in 2-3 weeks (depending on customization). Due to the nature of the firearms market, it may take longer.

Our Legacy uppers are a fully custom product. These are not off the shelf items. Most of the legacy components are custom made for us. Due to lack of availability, do not wait when you see something that is available to order. If you see a add to cart, we have the components to build the upper. Once we are out it will be a while before we have more.

Since they are custom builds, we require deposit paid in full at time of order. All custom builds do have a 50% nonrefundable deposit.

Business days are counted as Monday through Friday excluding Federal Holidays.

Our website does not display live inventory, while we stock most of our products we may run out from time to time. If you do not see the add to cart button, we are not taking orders for that item. We will notify you as soon as we know of a problem.

21. What is the difference between a A2 Front sight and a F-Marked?

About .040 in height, Simplest answer is to use a F-Marked for a Flattop A3 upper, and a A2 for a fixed carry handle.

22. Do you use taper pins to install your Front Sight Base?

Yes.

23. Are your barrels coated (finished) under the Front Sight Base?

Yes, we install the FSB after the barrel is finished per Mil-Spec.

24. Gas Port Size

Our 10.5" 5.56 barrels use a .076 gas port orange dot, 11.5” .070

12.5", 13.9", and 14.5" 0.70 (carbine) yellow dot .081 (mid) blue dot, 16" .070 (carbine) yellow dot .081 (Mid) blue dot and 20" .095 White dot.

25. Custom Uppers and customization

We do offer custom services; we will try to accommodate your request if possible. You do need to contact us prior to order for product changes.

26. Do you take orders over the phone?

For security reasons our system is set up to only process orders electronically. This is to protect the security of your card information. We are unable to push an order through manually.

27. Do you have a store front?

At this time, we do not have a walk-in retail location.

28. I forgot my password and the link isn't working?

Email us with your login info and we will send you a temporary password.

29. Why is the inside of my upper grey?

You're seeing the dry film lube coating.

30. What does manual verification mean?

Something about your order triggered our fraud settings. For your order to go forward you will need to email a copy of your state ID to sales@tntesales.com. Make sure to include your order number.

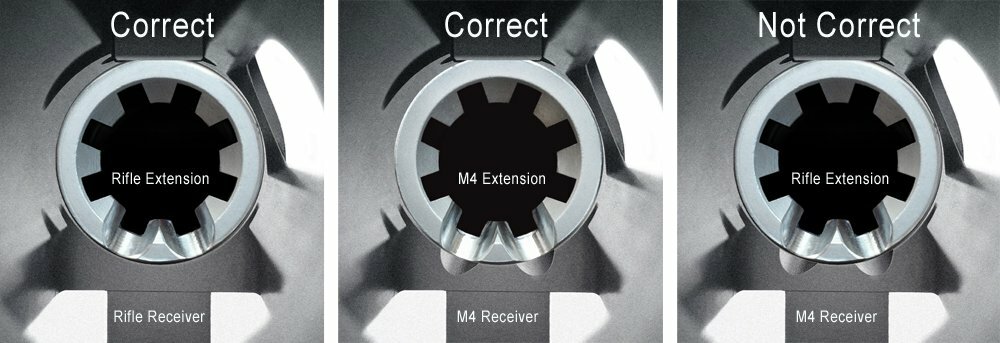

32. What are M4 ramps

M4 ramps are standard on all our 5.56 1/7,1/8,and 1/9 barrel. 1/12 and 1/14 barrels have rifle ramps unless otherwise stated.

32. I want to use my po box as my physical address.

To do this you must address it in this format,

If your order is small parts just put the PO Box in for the address.